CX 3200 a product of Nowy Styl

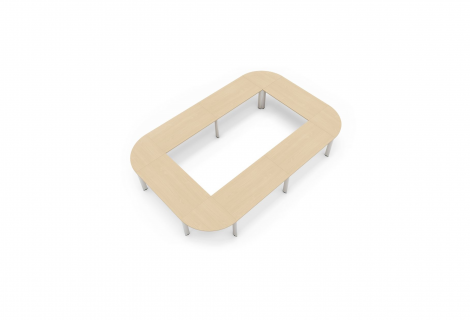

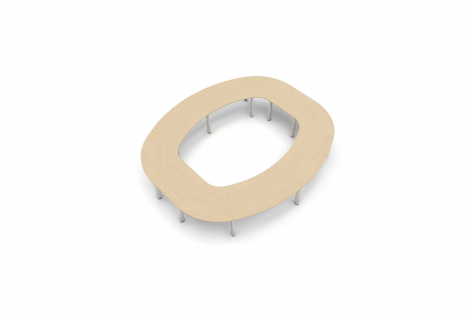

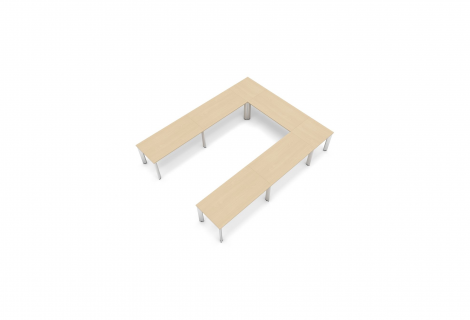

Modern and convincing design are not the only unique selling points of this table system. The quick, easy and, above all, tool-free assembly as well as the variety of setup options are convincing arguments for the CX 3200 table system. Thanks to the innovative table leg assembly system, fewer table legs are required. This not only improves the look, but also creates more seats.

Limitless variety

The flexibility of the CX 3200 table system is primarily due to the variety of table top shapes and sizes. In combination with the intuitive table leg assembly, the system offers an almost endless configuration potential.

Patented mounting method

All table tops in the system are equipped with steel plates on the underside, to which the table leg is attached with just two small levers. Installation is easy, quick and requires no tools at all. Thanks to the special mechanism, only one table leg has to be mounted at the connection point between two table tops, which reduces the number of table legs and provides more free space under the table.

product finishes

Typical of the CX 3200 system are the frameless construction and the quick, patented assembly of the table legs and table tops. CX 3200 is a modular system and offers almost unlimited possibilities of arrangement with a minimum number of table legs. The table top is made from a five-layer blockboard with a total thickness of 32 mm. At its core, it consists of 22 mm thick poplar wood strips with a density of 470 kg/m³, glued to a 1 mm thick veneer sheet and a 3 mm thick MDF board. Depending on the customer's requirements, the tabletop surfaces are made of veneer or laminate. The underside of the table top is coated with gray laminate. Table tops with a laminate surface have a 2 mm ABS edge, while veneer surfaces have a natural veneer edge (thickness 2 mm). The CX 3200 connecting plate consists of die-cast aluminum (powder-coated RAL 9006) to which the table base made of 2 mm thick anodised aluminum profile is attached. Alternatively, the base is available powder-coated in white (RAL 9016) with a matching white die-cast aluminum connecting plate. There are two possible positions for the legs. For externally mounted table legs, the steel plates used for leg assembly are placed 5 mm from the edge of the table top. All tabletop depths can be planned. With recessed table legs, the steel plates for mounting the legs are placed 5mm from the rear edge of the tabletop and 255mm from the edge of the tabletop on the user side. All table top depths can be planned, except for the 700 mm deep and square table tops. The table legs are provided with a leveling screw (± 10 mm). Optionally, these leveling screws are also available with a felt covering. A mechanism for connecting the table legs to the table top is built into the table legs. The table feet are firmly connected to the tabletop by means of a double counter-pull and can be easily detached again. It is operated using stable plastic levers on the upper side of the table feet. Total table height: 740 mm (top 32 mm, table feet 708 mm)..

Awards & Zertifikate

DESIGN: Jens Korte

AFTER JENS KORTE COMPLETED HIS STUDIES IN INDUSTRIAL DESIGN UNDER PROFESSOR DIETER RAMS AT THE HAMBURG ACADEMY OF FINE ARTS, HIS INITIAL PROFESSIONAL ASSIGNMENTS INCLUDED WORK AS DESIGNER AND DESIGN MANAGER FOR THE COMPANIES FROGDESIGN AND WIEGE IN GERMANY, USA, AND JAPAN. SINCE 1999 KORTE HAS WORKED AS A FREELANCE DESIGNER AND AS THE HEAD OF HIS OWN AGENCY: JENS KORTE DESIGN, IN HAMBURG.