QUESTIONS ON THE SELECTION OF FURNITURE MATERIALS

Before you approach the selection of furniture material, you should clearly realize which of your requirements the material must satisfy – and what you expect from the material used in your furniture.

The price of furniture material reveals nothing about its characteristics: for example, its durability, the care required, soiling behaviour and the light-fastness of the material used in the furniture. The sum total of its characteristics indicates the quality of a material.

We employ only high-quality materials. Our collection information provides the quality characteristics and the quality grade of the materials we use. The quantity of material used per model depends on calculations for the design of our furniture covering material. If the customer provides the cover material, coordination with us is required according to material characteristics, including provision of samples or strips.

TEXTILE FIBRE MATERIALS

The origin of a fibre can allow conclusions on its characteristics. In turn, these conclusion have decisive influence on the quality of the material.

Distinction is drawn between natural and synthetic fibres. Further distinction is made for natural fibres between those of plant and those of animal origins.

For synthetic fibres, further distinction is drawn between natural polymers and synthetic polymers.

NATURAL FIBRES

COTTON

Cotton yarn is manufactured from the long seed fibres of the cotton boll.

Similarly to wool, cotton is exceptionally resistant to mechanical and chemical influences. It demonstrates good tear resistance, especially good wet strength and good abrasion resistance. In addition, it is relatively resistant to heat. Although cotton fibres soil much more quickly than do wool fibres, they are easily to clean.

EIGENSCHAFTEN:

- atmungsaktiv

- gute Feuchtigkeitsaufnahme

- gute Reissfestigkeit

- zufriedenstellende Scheuerfestigkeit

- geringer Glanz

- elektrostatische Aufladung nur sehr gering

- gut zu Bleichen und zu Färben

- säureempfindlich

ANIMAL FIBRES

WOOL / SHORN WOOL

Wool is the designation for the hair of a sheep. Shorn wool is the designation of wool shorn only from living sheep. Wool quality is assessed according to the uniformity and the fineness of the wool hair. The length, thickness, curliness and gloss of the wool are important for their characteristics for use in furniture material.

Shorn wool compensates for temperature changes and can absorb up to one-third of its own weight in moisture, without feeling wet. Owing to its wool grease, shorn wool is naturally resistant to soiling and is somewhat resistant to fire. When wool fibres come near a flame, they draw back and burn – if they nevertheless catch fire – with only a small flame that is easily to extinguish. A distinction must be drawn to carded yarn (i.e., fulled yarn, with its slightly rough surface) and to worsted yarns with their significantly smoother and finer surface structure.

Shorn wool consists of many cells that have naturally developed. The exterior of the fibre cortex is covered with cuticle, whose sections remind us of roofing tiles as the lie over each other. The interior of the cuticle contains spindle-shaped cells. The individual cuticle cells of the fibre cortex are enclosed by fine, thin skin.

PROPERTIES

- Gentleness to the skin

- Breathability

- Great moisture absorption

- Good thermal insulation

- Moderate to great abrasion resistance

- Good strain values

- Good wrinkle recovery

- Sensitivity to hot water and steam

- Sensitivity to caustic and alkaline agents

- Susceptibility to insect infestation

- Fire resistance

SYNTHETIC FIBRES:

VISCOSE

Viscose is considered a synthetic fibre, although its basic substance is cellulose. The cellulose is obtained from beech and pine wood. An elaborate process purifies and chemically modifies the wood fibres. Like cotton and shorn wool, viscose is very absorbent and therefore has good hygienic properties. Viscose is frequently sold in combination with other materials, which thereby provide it with greater durability. It is possible to treat viscose so as to be flame-retardant. One example of this possibility is the fibre Lenzig FR, which – in addition to applications in upholstery – is also frequently used for protective clothing

PROPERTIES:

- Very good absorbance of moisture

- Soft feel

- Good dyeability

- Less wet strength than cotton

POLYESTER

Polyester is a completely synthetic fibre, which exhibits very good tear and abrasion resistance, as well as excellent elasticity. Textiles made of polyester hold their shapes very well, are resistant to wrinkling and are especially easy to clean. A special impregnation of polyester fibres renders them fire-resistant.

PROPERTIES:

- Great tear resistance

- Great durability

- Great rubbing fastness

- Substantial stretchability and elasticity

- Slight absorbance of moisture

- Sensitivity to heat

- Resistance to mould

- Great resistance to fading

- Good ability to keep its shape

Trevira CS

Trevira CS is a polyester variant that is accordingly very durable and easy to keep clean. It is characterized by good colour fastness and light fastness. Trevira CS differs from basic polyester by its permanent flame-retardant properties. This results not from additional impregnation, but from a comonomer integrated into the fibre polymer. After the source of fire has extinguished, materials made of Trevira CS extinguish automatically.

PROPERTIES:

- Permanent flame-retardation

- Great tear resistance

- Great durability

- Great rubbing fastness

- Substantial stretchability and elasticity

- Sensitivity to heat

- Slight absorbance of moisture

- Resistance to mould

- Great resistance to fading

- Great colour fastness

- Good ability to keep its shape

POLYACRYLIC FIBRES

Particularly characteristic of polyacrylic fibres are their feel similar to wool, their low density, good resistance to light and chemicals as well as their ease of cleaning and being cared for.

PROPERTIES:

- Great tear resistance

- Great durability

- Great rubbing fastness

- Good ability to keep their shape and to puff up

- Resistance to shrinkage

- Good dyeability

- Great resistance to fading

- Stretchability and elasticity

- Slight absorbance of moisture

- Fast drying

- Ease of caring for

MICROFIBRES

Microfibre is a term used for furniture material with a velvet-smooth upper surface similar to suede. This synthetic suede-like material, known as vortex fleece, consists of ultra-fine polyester fibres (microfibres) together with polyurethane. Microfibre fleece materials are produced by various production processes. Well-known brands include Alcantara, JABANA and VIVANA.

PROPERTIES:

- Great durability

- A very pleasant feel

- When stroked by fingers, the very finely structured upper surface tends to cause a slight pile shift, which produces a light-and-shadow effect (“the writing effect”).

- Tendency to form an impression of the user’s seatprint

QUALITY CRITERIA

ABRASION RESISTANCE

The resistance of a furniture material against abrasion (i.e., to wear) is designated as abrasion resistance. This criterion therefore give information on how break-resistant a fibrous fabric is. Tests are generally conducted with the Martindale method. This technique circularly abrades one material against another. The abrasion lasts as long as at least two threads are broken. The optical impression is not used here. If furniture material is used in an office, a Martindale value of 40,000(or more) abrasion cycles is recommended.

PILLING BEHAVIOUR

Pilling means the formation of small knots on the surface of fabrics. They form when individual fibres from the middle part of a fibre complex work themselves out and form knots with additional fibres. Pilling can also form as so-called external pilling, when pilling knobs from pieces of furniture users’ clothing cling to the upholstery or covering material.

Testing for intrinsic pilling takes place as part of the abrasion cycle test and is valuated on the basis of a 5-stage scale.

Pilling stage 1 = very extensively pilled

Pilling stage 2 = virtually no change with respect to the untested material

Illustration of the development of pilling, in 5 stages

When pilling occurs, it can be removed by using a lint-removal device. This method removes the pilling without damaging the material.

COLOUR FASTNESS

During this test, the material is subjected to artificial ultraviolet light. After a defined lightexposure time (typically, 100 hours = 4 years of daylight), the bleaching of the material is numerically rated by use of an 8-stage scale.

Light fastness 1 = only very slight resistance to fading (maximum colour change)

Light fastness 8 = very great resistance to fading (minimal colour change)

Upholstery material should demonstrate a value of at least 5.

RUBBING FASTNESS

Tests are conducted on the colour fastness of a fabric. Two tests are conducted, during which a dry and a wet white cotton cloth is rubbed against the material to be tested. The colour staining of the cotton cloth is valuated on a 5-stage scale.

Colour fastness 1 = maximum colour staining

Colour fastness 5 = no colour staining

For approval of upholstery fabrics, rubbing with dry material must achieve a value of at least 3 – 4, and a value of 3 for rubbing with wet material.

FIRE RESISTANCE

There are many procedures for testing the fire resistance of textile material. The most important of these procedure are described below:

- European standards

EN 1021 – Part 1 / Cigarette Test

Here, a burning cigarette is placed in a corner of the test model. After 60 minutes, the fabric must no longer glow or burn.

- EN 1021 – Part 2 / Match Test

This test is not actually conducted with a match: instead, with a 35-mm butane flame. The flame is applied for 15 seconds to a corner of the test model. After the flame is removed, the material must not begin to burn within 2 minutes.

- German standards

DIN 4102 – B1 / Fire Shaft Test

The designation “fire shaft” refers to the test equipment. It consists of a vertical fire shaft (chimney) and a gas burner. The tested materials are secured vertically in a mounting frame and are subjected to the flames for 10 minutes. During this time, a constant flow of air is directed through the shaft. Assessment criteria are the flue-gas temperature resulting, and the residual length of the not-burned share of the material.

- DIN 4102 – B2 / Small Burner Test

The material test sample is suspended vertically in a frame and subjected for 15 seconds to a 20-mm flame from a gas burner. Values are provided to assess the development of flame and the question as to whether flame residue dripped.

- Great Britain BS 5852In this test procedure, a corner of a test model is subjected to 8 different sources of flame: i.e., cigarettes, butane flames, and wood flame at various intensity levels. The first two test stages (the cigarette test and the match test, simulated by a 35-mm butane flame) correspond to the European standards.

BS 7176 represents a more stringent test version. In this test, the tested material is previously soaked in water and then dried, to remove easily separated chemical treatment. In addition, for the test model, cushioning foam is used that demonstrates poorer behaviour when subjected to the influence of fire.

As a third special feature in comparison to the basic test BS 5852, four endangering categories are defined in the regulations in BS 7176, and these categories are linked to the requirements placed on the fire resistance of the material being used. In this context, office rooms fall into the lowest endangering category; prison cells are in the highest category.

ELECTROSTATIC CHARGE

Electrostatic charges can result by rubbing between furniture materials and clothing textiles. Increase in humidity – e.g., by the use of room humidifiers – is possible to mitigate this development. Introductory remarks Especially designed conducting furniture-cover materials are of course available (option EH). The conductivity here takes place through the material to earth.

CARE AND CLEANING OF FURNITURE MATERIALS

As with all materials in daily use, furniture materials also require regular care; they are also subject to continuous soiling by dust and human contact. As a general rule, one should not allow soiling to become extreme, in order to prevent more intensive cleaning measures, and to lengthen the service life of the furniture. Proper care and cleaning preserve the utility value of your furniture.

For bright colours, visible soiling is greater than for darker colours. For this reason, lightercoloured coverings should be cleaned at shorter intervals, in accordance with the intensity of their use. One example here is vacuum cleaning with the use of a special upholstery attachment. CAUTION: The upholstery attachment used must not have ragged or sharp edges that would damage the furniture material.

Be careful to observe the scouring and abrasion resistance of the furniture material. Determination of this resistance can reveal how often furniture material can be cleaned without impairing the optical appearance of the materials.

BEFORE CLEANING:

Before choosing a suitable cleansing agent, preliminary testing is necessary. Care should be taken that pH-neutral agents are used. Acidic cleansers damage cotton and cellulose materials, and alkaline cleansers are not suitable for wool materials. For effective spot removal and cleaning, complete washing-out of the cleansing agent (surfactant) is necessary after cleaning. Otherwise any residue here will later lead to faster soiling.

Important

First remove dust. Then check the colour fastness and the surface changes in the furniture material as a result of using cleansing agent: use a white, soft, clean cloth soaked in cleansing agent or spot remover and apply it to a concealed area of the furniture. This test must also be conducted for natural-coloured furniture material. After the test area has dried, check the results of using the cleansing agent there.

CLEANSING BY THE USER

Cleansing by the user consists of three steps:

- Upkeep care

- Spot remover

- Intermittent cleaning

Caution! Thorough cleaning must be performed by a specialist in cleaning upholstered furniture. Spots on textile furniture materials can be removed most easily immediately after they occur. Be careful with furniture material made of cotton, linen, silk, and viscose. Please have these materials cleaned by companies specializing in cleaning.

Dab off moist spots with an absorbent paper tissue or with paper. Remove and residue with diluted carpet and upholstery shampoo. Never apply cleansing agent directly to the furniture: first, apply the cleanser to a white cloth, and then from the cloth to the furniture material.

MAINTENANCE CARE

STAIN REMOVAL

Dab off moist spots with an absorbent paper tissue or with paper. Remove and residue with diluted carpet and upholstery shampoo. Never apply cleansing agent directly to the furniture: first, apply the cleanser to a white cloth, and then from the cloth to the furniture material. Use this cloth to remove the spot by starting at its edge and moving to the middle of the spot. Then use a moist cloth to rub off any shampoo remaining.

Careful! Rubbing can cause changes in the surface of the furniture material. Always perform the final cleansing in the direction of rubbing. In all cases, ensure that upholstered furniture dries immediately, and do not use it until it has completely dried out. If you encounter insoluble residue of spots, or if spots remain, moisten a white cloth with cleaning solvent and dab the spot.

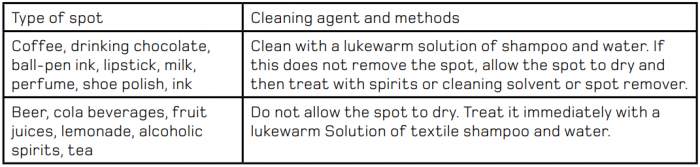

Water soluble stains

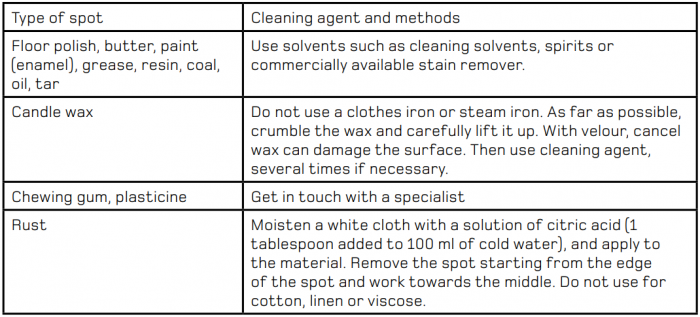

Water insoluble stains

INTERMEDIATE CLEANING